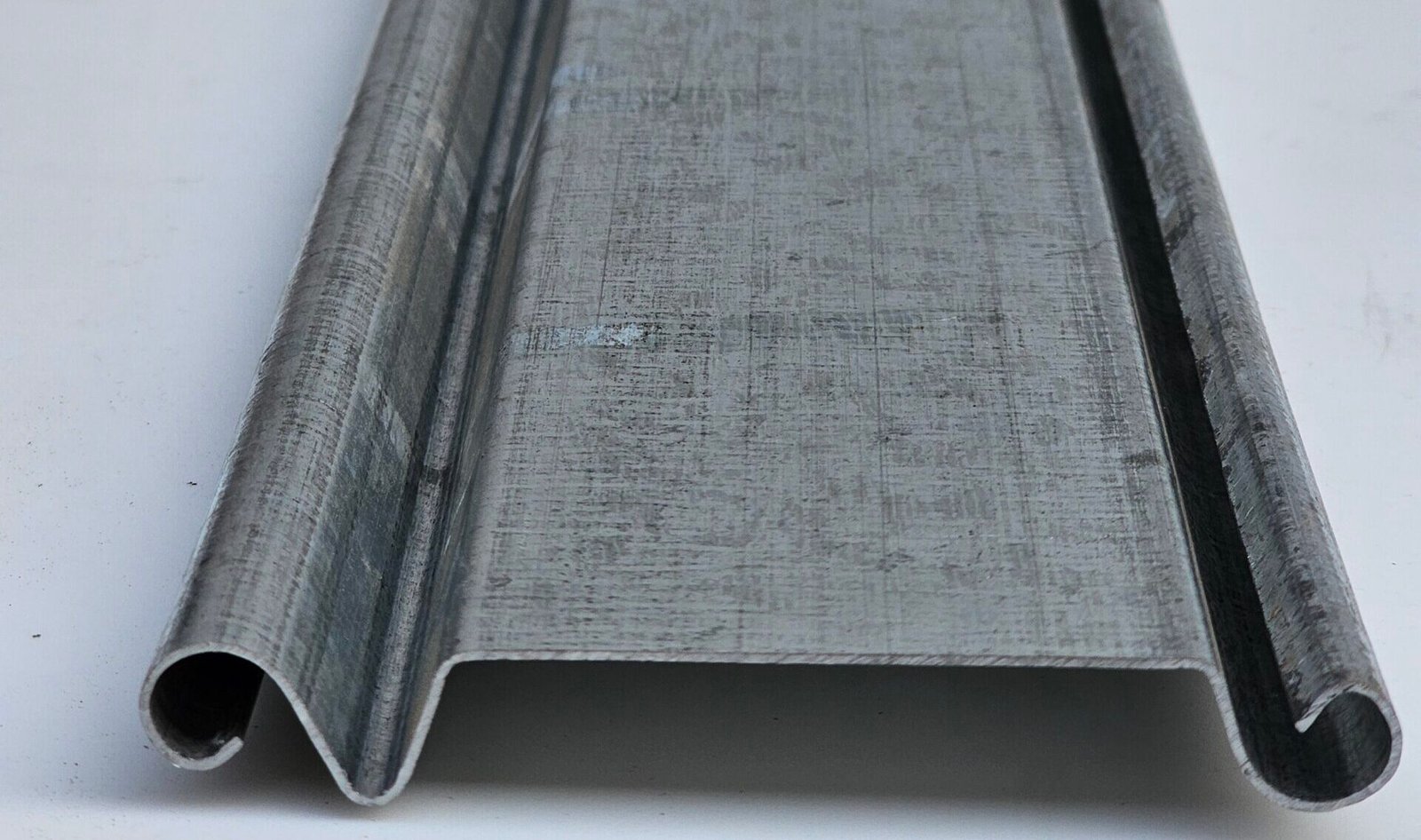

A Profile Shutter Strip is a vital component in the construction of roller shutters and doors, providing an effective solution for securing entrances while offering durability and aesthetic appeal. It typically consists of high-quality materials such as aluminum or galvanized steel, ensuring long-term performance in both residential and commercial settings.

For your website WonderMachinesIndia, a dedicated page on the Profile Shutter Strip would focus on its features, such as:

Durability: These strips are designed to withstand wear and tear, corrosion, and various weather conditions.

Customization: Offering different sizes and finishes to meet specific customer needs.

Functionality: Enhances the smooth operation of roller shutters by ensuring secure and tight closures.

Applications: Ideal for various sectors like retail, garages, warehouses, and industrial spaces.

Easy Installation:

These strips are engineered for quick and easy fitting, adding convenience to the installation process.

These strips are engineered for quick and easy fitting, adding convenience to the installation process.

This page can also highlight the technical specifications, advantages, and different available models, alongside the benefits of choosing WonderMachinesIndia for high-quality, reliable products.

You said:

ChatGPT said:

The process of making rolls (often referring to rolled metal products, such as sheets or coils, or roller shutters used for security) involves several stages, depending on the specific type of roll you’re referring to. Here’s a breakdown of both scenarios:

1. Process of Making Rolled Metal Products (Sheets or Coils)

This process involves converting raw metal (usually steel or aluminum) into thin sheets or coils that can be used for various industrial applications, including manufacturing roller shutters, roofing, and other products.

a. Preparation of Raw Material

Metal Slabs: The process starts with large metal slabs or ingots. These slabs are usually made from steel, aluminum, or other metals.

Cleaning: The slabs undergo cleaning to remove any surface impurities like oxides or rust, which might affect the final product quality.

b. Heating and Reheating

Hot Rolling: The slabs are heated in a furnace to a high temperature, making them easier to manipulate. The heated metal is then passed through large rollers (known as a rolling mill) to reduce its thickness. This process is known as hot rolling.

Cold Rolling: After the metal has been initially rolled, it might undergo a secondary process called cold rolling, where the metal is cooled and further reduced in thickness, producing a smooth finish and finer gauge metal sheets or coils.

c. Rolling Process

The metal passes through multiple sets of rollers, where the metal is flattened into thinner sheets or rolled into coils. These rollers apply pressure, which compresses the metal to the desired thickness.

Roller Configuration: The setup may involve different rolling configurations like single-pass rolling or multi-pass rolling, depending on the thickness and finish needed.

d. Cooling and Cutting

The rolled metal is then cooled, either by air or water, to stabilize the material.

Once cooled, the metal is often cut into the desired lengths or coiled into rolls for easier handling and transportation.

e. Surface Treatment

Depending on the final use, the rolled metal might undergo additional treatments like coating, galvanizing (to prevent rust), or painting.

2. Process of Making Roller Shutters (with Profile Shutter Strips)

The process of making roller shutters or shutter strips involves creating a durable and functional system for security, typically using materials like steel, aluminum, or a combination of metals.

a. Material Selection

Metal Profiles: The metal used for shutter strips is selected based on strength, flexibility, and resistance to corrosion. Most commonly, aluminum and galvanized steel are used.

b. Roll Forming

Roll Forming: In this process, the metal strips are passed through a set of rollers that shape them into a specific profile. The rollers gradually form the desired shape of the shutter strip, which could be flat, curved, or designed to interlock with other strips. The roll forming machine ensures consistent dimensions throughout the production.

c. Cutting and Shaping

Once the strips are formed, they are cut to the desired length using automated cutting machines. This allows for precision and uniformity across all shutter strips.

d. Assembly of Shutter Slats

After individual shutter strips are cut, they are connected together to form the slats of the roller shutter. This is done by aligning the slats and ensuring the interlocking profiles work seamlessly for smooth operation.

e. Finishing and Coating

The strips might undergo a finishing process, such as powder coating or anodizing, to enhance their appearance, corrosion resistance, and longevity.

f. Final Testing and Quality Control

The final roller shutters are tested for their functionality, ensuring they can be rolled up and down smoothly, are secure, and meet the required safety standards.

Summary

The process of making rolls—whether it’s rolled metal products or roller shutters—involves careful material selection, heating, rolling, forming, and finishing to achieve the desired shape, strength, and quality. In the case of roller shutters, additional steps like assembly, coating, and testing are included to ensure the final product meets the durability and functional needs of customers.

A Profile Shutter Strip is a vital component in the construction of roller shutters and doors, providing an effective solution for securing entrances while offering durability and aesthetic appeal. It typically consists of high-quality materials such as aluminum or galvanized steel, ensuring long-term performance in both residential and commercial settings.

For your website WonderMachinesIndia, a dedicated page on the Profile Shutter Strip would focus on its features, such as:

Durability: These strips are designed to withstand wear and tear, corrosion, and various weather conditions.

Customization: Offering different sizes and finishes to meet specific customer needs.

Functionality: Enhances the smooth operation of roller shutters by ensuring secure and tight closures.

Applications: Ideal for various sectors like retail, garages, warehouses, and industrial spaces.

Easy Installation: These strips are engineered for quick and easy fitting, adding convenience to the installation process.

This page can also highlight the technical specifications, advantages, and different available models, alongside the benefits of choosing WonderMachinesIndia for high-quality, reliable products.

You said:

ChatGPT said:

The process of making rolls (often referring to rolled metal products, such as sheets or coils, or roller shutters used for security) involves several stages, depending on the specific type of roll you’re referring to. Here’s a breakdown of both scenarios:

1. Process of Making Rolled Metal Products (Sheets or Coils)

This process involves converting raw metal (usually steel or aluminum) into thin sheets or coils that can be used for various industrial applications, including manufacturing roller shutters, roofing, and other products.

a. Preparation of Raw Material

Metal Slabs: The process starts with large metal slabs or ingots. These slabs are usually made from steel, aluminum, or other metals.

Cleaning: The slabs undergo cleaning to remove any surface impurities like oxides or rust, which might affect the final product quality.

b. Heating and Reheating

Hot Rolling: The slabs are heated in a furnace to a high temperature, making them easier to manipulate. The heated metal is then passed through large rollers (known as a rolling mill) to reduce its thickness. This process is known as hot rolling.

Cold Rolling: After the metal has been initially rolled, it might undergo a secondary process called cold rolling, where the metal is cooled and further reduced in thickness, producing a smooth finish and finer gauge metal sheets or coils.

c. Rolling Process

The metal passes through multiple sets of rollers, where the metal is flattened into thinner sheets or rolled into coils. These rollers apply pressure, which compresses the metal to the desired thickness.

Roller Configuration: The setup may involve different rolling configurations like single-pass rolling or multi-pass rolling, depending on the thickness and finish needed.

d. Cooling and Cutting

The rolled metal is then cooled, either by air or water, to stabilize the material.

Once cooled, the metal is often cut into the desired lengths or coiled into rolls for easier handling and transportation.

e. Surface Treatment

Depending on the final use, the rolled metal might undergo additional treatments like coating, galvanizing (to prevent rust), or painting.

2. Process of Making Roller Shutters (with Profile Shutter Strips)

The process of making roller shutters or shutter strips involves creating a durable and functional system for security, typically using materials like steel, aluminum, or a combination of metals.

a. Material Selection

Metal Profiles: The metal used for shutter strips is selected based on strength, flexibility, and resistance to corrosion. Most commonly, aluminum and galvanized steel are used.

b. Roll Forming

Roll Forming: In this process, the metal strips are passed through a set of rollers that shape them into a specific profile. The rollers gradually form the desired shape of the shutter strip, which could be flat, curved, or designed to interlock with other strips. The roll forming machine ensures consistent dimensions throughout the production.

c. Cutting and Shaping

Once the strips are formed, they are cut to the desired length using automated cutting machines. This allows for precision and uniformity across all shutter strips.

d. Assembly of Shutter Slats

After individual shutter strips are cut, they are connected together to form the slats of the roller shutter. This is done by aligning the slats and ensuring the interlocking profiles work seamlessly for smooth operation.

e. Finishing and Coating

The strips might undergo a finishing process, such as powder coating or anodizing, to enhance their appearance, corrosion resistance, and longevity.

f. Final Testing and Quality Control

The final roller shutters are tested for their functionality, ensuring they can be rolled up and down smoothly, are secure, and meet the required safety standards.

Summary

The process of making rolls—whether it’s rolled metal products or roller shutters—involves careful material selection, heating, rolling, forming, and finishing to achieve the desired shape, strength, and quality. In the case of roller shutters, additional steps like assembly, coating, and testing are included to ensure the final product meets the durability and functional needs of customers.

Would you like more detailed information on any of these processes?

Would you like more detailed information on any of these processes?